Smart-thinking partnership of ITSS Engineering and Hydraulink delivers safe, efficient, and environmentally sustainable world beater SMART-DIG Hydro Excavator

A partnership between experts in complementary fields of engineering and services has helped produce a Kiwi-made hydro excavator designed to be among the most advanced, reliable, and operator-friendly of its type in the world.

ITSS Engineering in Warkworth has worked with the national Hydraulink hydraulic hose and fittings group to produce essential hydraulic kits for the compact and ultra-reliable SMART-DIG hydro excavator models, initially for NZ, but with variants earmarked for export.

SMART-DIG is a partnership between Southey's Group and ITSS Engineering, with which Hydraulink has worked with for over 10 years in the development and proving of hydraulic hoses and fitting kits for the broader SMART-DIG ranges, including HX-2000, HX-4000, and HX-6000 variants sold in NZ, Australia, and North America.

The SMART-DIG family of hydro-excavators combine high pressure water to cut through soil with an air vacuum for debris extraction, to provide a safe, swift, cost-effective, and non-invasive alternative to conventional digging and trenching without damaging already existing services or tree roots. SMART-DIG excavators are widely used on building and construction, landscaping, municipal, and transport projects as well as public, private, commercial, and industrial development, and infrastructure worksites involving plumbing, trenching, landscaping and civil contractors.

Mark Harris, Workshop and Smart-Dig Manager, ITSS Engineering Ltd worked with Hydraulink Area Sales Manager Doug Stewart to evolve the hydraulic hose fittings kits involved in the wide variety of control and actuation required in the user-friendly and versatile SMART-DIG range.

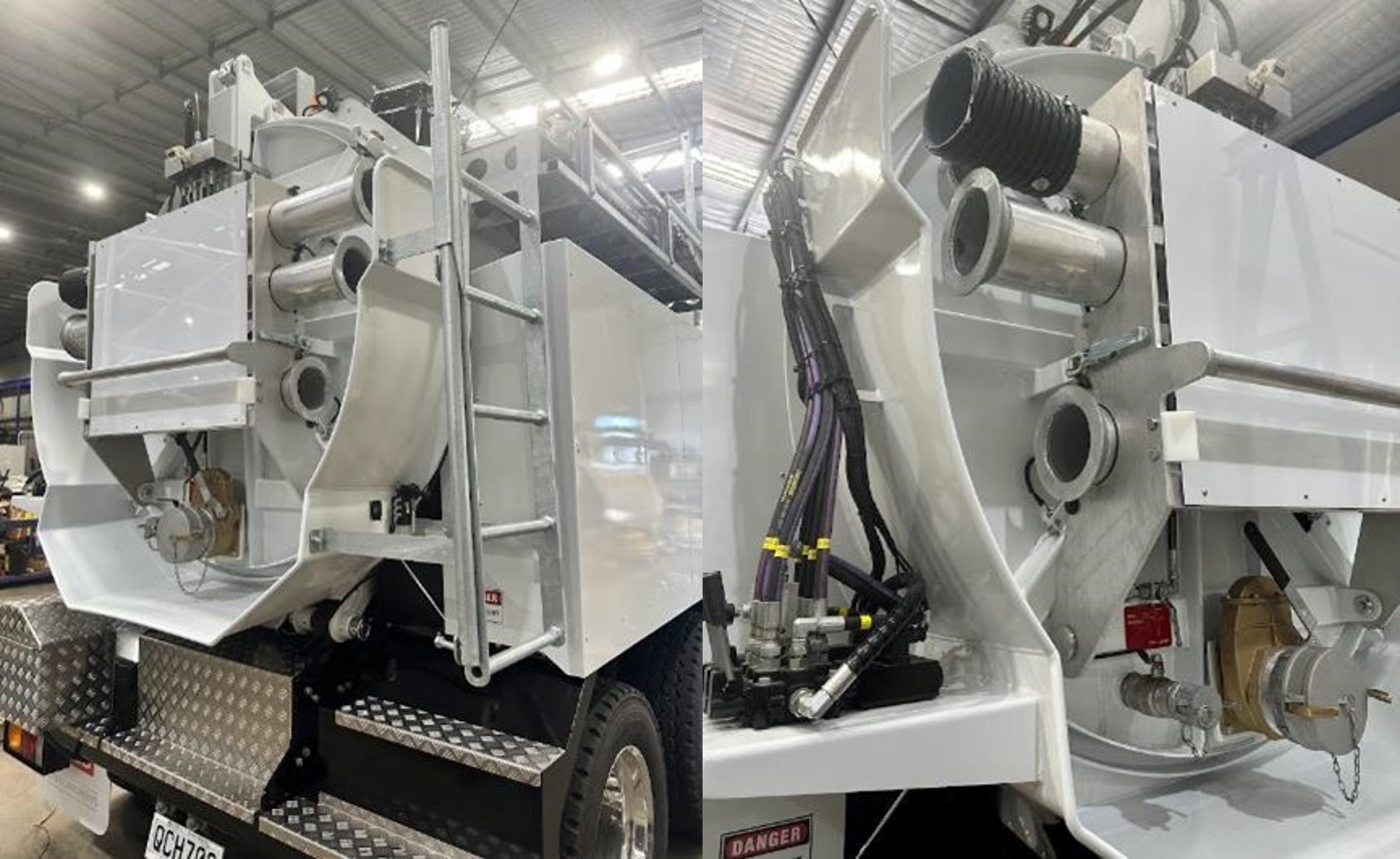

The business end of the HX-6000, left, showing the type of simplistic hydraulic engineering, right, to make it all work reliably with minimised downtime.

Mark Harris says one of the many advances of the SMART-DIG range is found in its Drop Box filtration system. Conventional hydro-excavators use cyclone filtration systems, which can be erratic – they only work properly at a constant airflow. “We engineer the SMART-DIG Drop Box to be a filtration system that works efficiently regardless of variable airflow. This means better suction, better excavation, and less downtime. Another strong feature of the HX-6000 is its dual water blasters, which facilitate two technicians digging in unison to complete jobs quicker than others with single water blasters”.

Development of reliable hydraulic connection kits (such as these above, within the HX-6000) are a continuous field of broad expertise within the Hydraulink network encompassing New Zealand and Australia.

Doug Stewart says Hydraulink and ITSS Engineering worked closely together to develop hose kits that achieved the standards of constant evolution, reliability, and user-friendliness essential to optimising productivity and safety.

“Hydraulink makes hose kits for SMART-DIG as an OEM and has done so since we progressed from the prototyping stage nearly ten years ago. This engineering partnership has saved on costs and assembly times, helping Smart Dig keep manufacturing costs lower. Plus, all hoses specs are on record, meaning a hose can be made up rapidly if a replacement is needed anywhere in the country,” he says.

Trading under its market signature “Best under pressure,” the NZ Hydraulink network of more than 250 service points prides itself on delivering consistent world-class standards of service, components, compliance, and traceability across multiple sites. This same philosophy of consistently outstanding work and reliability is shared by the networks of Hydraulink and Hydraulink CCR in Australia, and the growing operations is SE Asia and the West Coast of the US.

HX6000 ready for work.

Mark Harris says, “The partnership with Hydraulink has been very valuable in the development of SMART-DIG’s range as a reliable machine for which there is strong industry demand. Like all construction and civil machinery, nearly everything the machine does so well depends on being reliable and well-designed”.

“The components, including the hydraulic kits used in the SMART-DIG range, have been specifically chosen to maximise performance and operational life. This gives operators significantly improved productivity, and reduced operating costs. We put our energy into building finely balanced machines that are more efficient, reliable, economical, and safer, so contractors can work with fewer disruptions,” he said.

“Our Hydro-excavators are designed by operators for operators – our machines benefit from constant upgrades based on broad experience gained on hydro-excavation contracts to meet the specific and unique demands facing operators. They are easy to operate – units utilise a wireless remote control that allows simple operation from a distance. The boom rotates a full 270 degrees and is power extendable.”

“They are built to last – Southey's Group, New Zealand's leading hydro-excavation company, tested these machines in the field for more than two years before releasing them to the market. SMART-DIG’s partnership between Southey's Group and ITSS Engineering brings more than 50 years of combined experience of mechanical engineering and operating hydro-excavation. Through this we have landed on a simple philosophy – make small improvements that collectively make a big difference on the job.”

HX4000 ready for work.

Hydraulink National Sale Manager Rob Naughton says, “The Smart-Dig range development was a perfect example of a true partnership delivering enduring value to both parties”.

“Shared values and goals with our valued partners are paramount to Hydraulink, whether we are designing hydraulic kits for the 2024 America’s Cup challenge, or investing our expertise to help customers achieve optimum results and greatest reliability from their complex industrial and civil engineering machinery.

“We pride ourselves on a can-do attitude, combined with globally respected standards of hydraulic service, and are delighted when we can share clearly demonstrated and ongoing productive values with a leading company such as ITSS Engineering”